Washing machines

A SOLUTION FOR EVERY CUSTOMER

At Fagor Professional, we adapt to the requirements of each business, offering a wide range of options. Fagor's new touch control offers outstanding efficiency, versatility, and connectivity features.

Our industrial washers provide the highest G Force on the market for minimum residual moisture and lower energy costs during the drying cycle. (available in low, medium, or high speed).

KARE CONTROL

The brain of your machine, under your control.

The new Touch Plus Control offers the user great flexibility thanks to its numerous functions: easy programming, full colour 7-inch touch screen, 37 available languages, USB port for updates and the same control system as for OPL and self-service washers.

All of our washers are equipped with a versatile and easy to use touch screen programming system with 29 pre-set programmes. These programmes can be modified while in operation. Additionally, you can create, export or import any new programmes through USB or WiFi.

The Touch Plus Control offers an innovative option that increases the earning prospects of self-service laundrettes as well as that of other people: advertising. Now you can include information about the times and prices on the washer itself, as well as the services offered and commercial messages from third parties, all in an attractive and eye-catching way.

Adding the right dose at the right time, with the right amount, gives us confidence in the process and the consistency of the result. And most importantly: peace of mind. 8 standard + 6 extra dosing signals (dosing time, delayed start, selection start) for all models.

BUILT FOR YOU

Designed for your welfare and comfort

The Kare generation has been designed with the comfort of the user in mind. That is why one of the construction specifications was to give the washing machines the largest sized doors on the market. This makes loading and unloading much easier and more ergonomic, especially for larger washing machines.

Both ergonomics and aesthetics have been taken into account in the plinth design: A) The plinths for the 11, 14, 18, 25 and 35 kg capacity models have been designed to keep the loading door at the same height across all models: 850 mm. This solution makes using trolleys easier and much more ergonomic. B) There are also plinths available for the same models with a different design to keep the same height across all the washing machines, specially designed for laundries.

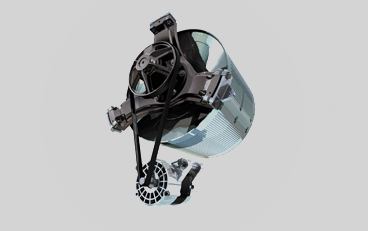

The bearings, bearing supports, motor and frequency inverter are equivalent to those in industrial machines.

Robust aluminium door with the same safety lock as in the industrial range.

It has the biggest door diameter on the market, with a diameter of 516 mm on the outside and a diameter of 373 mm on the inside. Easy to load and unload clothing.

Fagor offers the most versatile solution on the market for putting Wet Cleaning into practice. The machines are versatile, as both the washing machines and dryers offer the option to create different stages per programme, including all the customised parameters required by each detergent supplier in the Wet Cleaning industry.

The Kare range offers the option to customise the machines according to the specific requirements of each customer. Choose between the options available and we will send you the machines with these options already installed and factory tested.

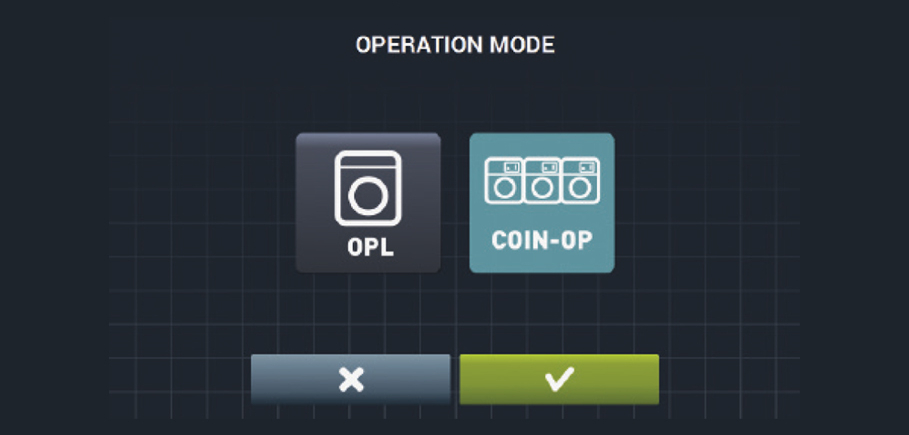

The machines can be transformed from OPL to Self-Service and vice versa via the TP2 control.

An electrical heating model can be easily transformed into a hot water model. A machine with a drainage valve can be converted into a machine with a pump.

EFFICIENCY

Technological innovations for a more sustainable machine.

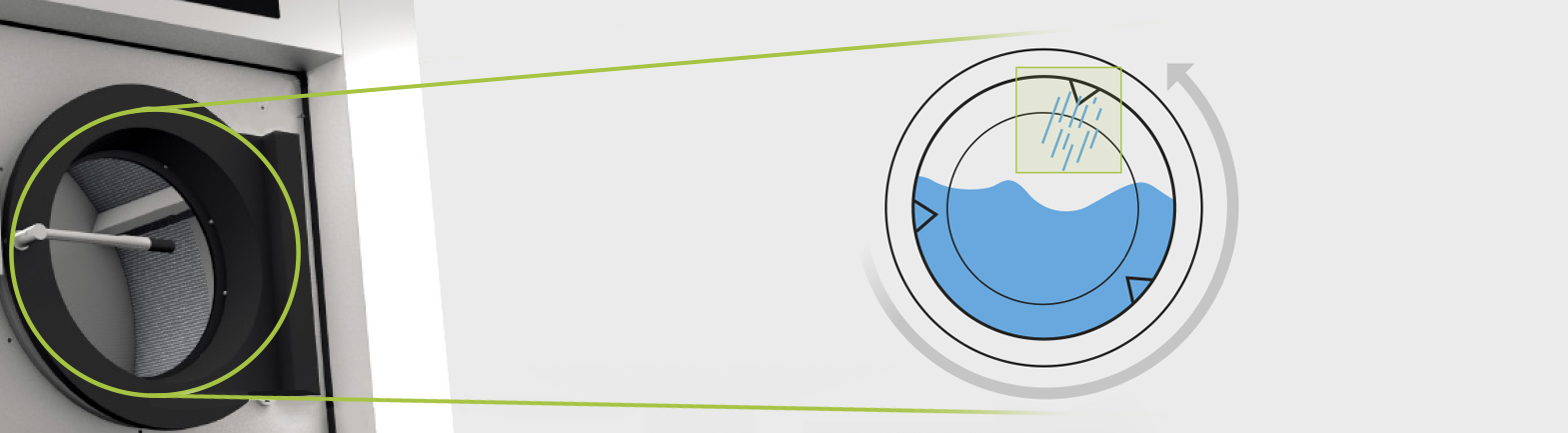

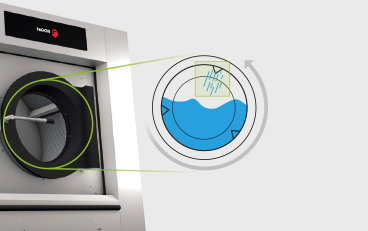

Kit for recirculating water from the tub to enhance its use. Improves effectiveness without mechanical action, for the best clothing care.

- Can be activated during any washing stage.

- Can be applied to any washing machine model.

- Less mechanical action in the drum.

- More water flow with chemicals.

- Uses all the water in the tub, even the water in the drainage pipe which is not usually used.

- Better chemical mixing.

- Quick clothing compaction.

An automatic adjustment system carried out by the machine itself which cleverly regulates the consumption of water and detergent in accordance with the load entered. It also provides the option to enter the load weight manually. This results in considerable savings of energy, water, and chemical products.

Thanks to the advanced technological development of the Kare range, the machine is able to detect any type of imbalance in its operation in advance. This way, once the anomaly has been corrected, it carries out the job more smoothly, which lengthens the life of its components and reduces washing time and energy consumption.

In accordance with Fagor Industrial’s efficiency and sustainability standards, all washing machines from the Kare range are equipped to handle the Kare Recovery System. We care about the environment and also your pocket, which is why we offer energy and water saving solutions that also reduce running costs.

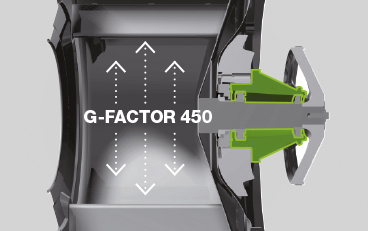

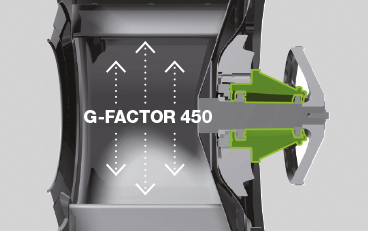

Fagor washing machines have the highest G Force on the market. This brings many advantages, such as a reducing the water retention in clothing and reducing the drying times. To sum up, they reduce running costs and save energy.

The effective design of the entire Kare washing machine range is based on a series of perforations on the edges of the drum with minimum space between this and the tank, allowing it to use only the energy required to heat the water while also reducing the superfluous use of chemical products.

Through a series of perforations in the machine paddles, it creates a water cascade effect that powers the mechanical action of the drum during operation and considerably reduces the amount of water needed for each wash.

Specially designed for laundries that prioritise the quality of the process as well as water and energy savings. The new industrial washing machines with high spin speed offer optimum performance and a revamped style to satisfy the needs of the most demanding customers.

This type of washing machine with high spin speed (G Force: 350 to 450) drastically reduces the residual moisture after the washing process, allowing for great savings in subsequent processes such as drying and ironing.

Its advanced design and technology, together with the wide range of options and accessories, have a significant impact on energy efficiency and on saving water and chemicals, reducing production costs and increasing the company’s productivity.

Its quick and easy installation as well as the minimum required space for it to be used and maintained are a key advantage in comparison to other ranges.

Washing machines with the same level of performance as the most sophisticated high spin washing machines. This range has been specially designed and conceived for those markets and customers who are looking for a simple washing machine.

The hard-mount machines with 200 G Force stand out due to their energy efficiency and low level of water and detergent consumption.

Washing machines frequently used by healthcare and social care centres. Essential for the process of washing sheets and other fabrics with solid contaminants, such as faecal remains or vomit.

Before adding the chemicals for washing, the washing machine carries out a cold water rinse, with maximum levels of water and constant agitation so that the solid contaminants are detached from the sheets. Thanks to the Ø 8 mm perforations in the drum, these solid elements easily leave the drum and are suspended in water which goes straight to the drain via the tank’s upper overflow (with dimensions increased to 3 inches to improve the process and prevent blockages).

Washing machines frequently used by healthcare and social care centres. Essential for the process of washing sheets and other fabrics with solid contaminants, such as faecal remains or vomit.

Before adding the chemicals for washing, the washing machine carries out a cold water rinse, with maximum levels of water and constant agitation so that the solid contaminants are detached from the sheets. Thanks to the Ø 8 mm perforations in the drum, these solid elements easily leave the drum and are suspended in water which goes straight to the drain via the tank’s upper overflow (with dimensions increased to 3 inches to improve the process and prevent blockages).